In the realm of 3D printing, precision is everything. One area that often demands meticulous attention is temperature control, particularly when it comes to the cooling fan. This is where OctoPrint PID fan control comes into play, offering users a powerful tool to fine-tune their 3D printers for optimal performance. Whether you are an experienced 3D printing enthusiast or just starting, understanding and implementing PID fan control in OctoPrint can significantly elevate the quality of your prints.

Understanding PID Fan Control in OctoPrint

OctoPrint PID Fan Control is a feature that allows users to regulate the fan speed in their 3D printer with incredible precision. PID stands for Proportional, Integral, and Derivative, which are the three components of the control loop used to maintain the desired fan speed and, by extension, the temperature.

Implementing PID fan control is crucial for achieving a stable and consistent temperature, which is essential for producing high-quality 3D prints. When you control the fan speed with PID, you can prevent sudden temperature drops or spikes, ensuring that the print process remains steady and predictable. This is particularly important when printing with materials that require precise temperature settings, such as ABS or PETG.

You may also read: How to Easily Install MiHoMo on Linux: A Complete Guide

Why Use OctoPrint for PID Fan Control?

OctoPrint, a powerful open-source software for 3D printers, provides an excellent platform for implementing PID fan control. Its versatility and wide range of plugins allow users to customize their 3D printing experience, making it easier to fine-tune settings such as fan speed.

Moreover, OctoPrint’s user-friendly interface simplifies the process of adjusting PID settings, even for those who are not well-versed in control systems. With OctoPrint, you can easily experiment with different PID values and see the results in real-time, which can be invaluable when trying to perfect your prints.

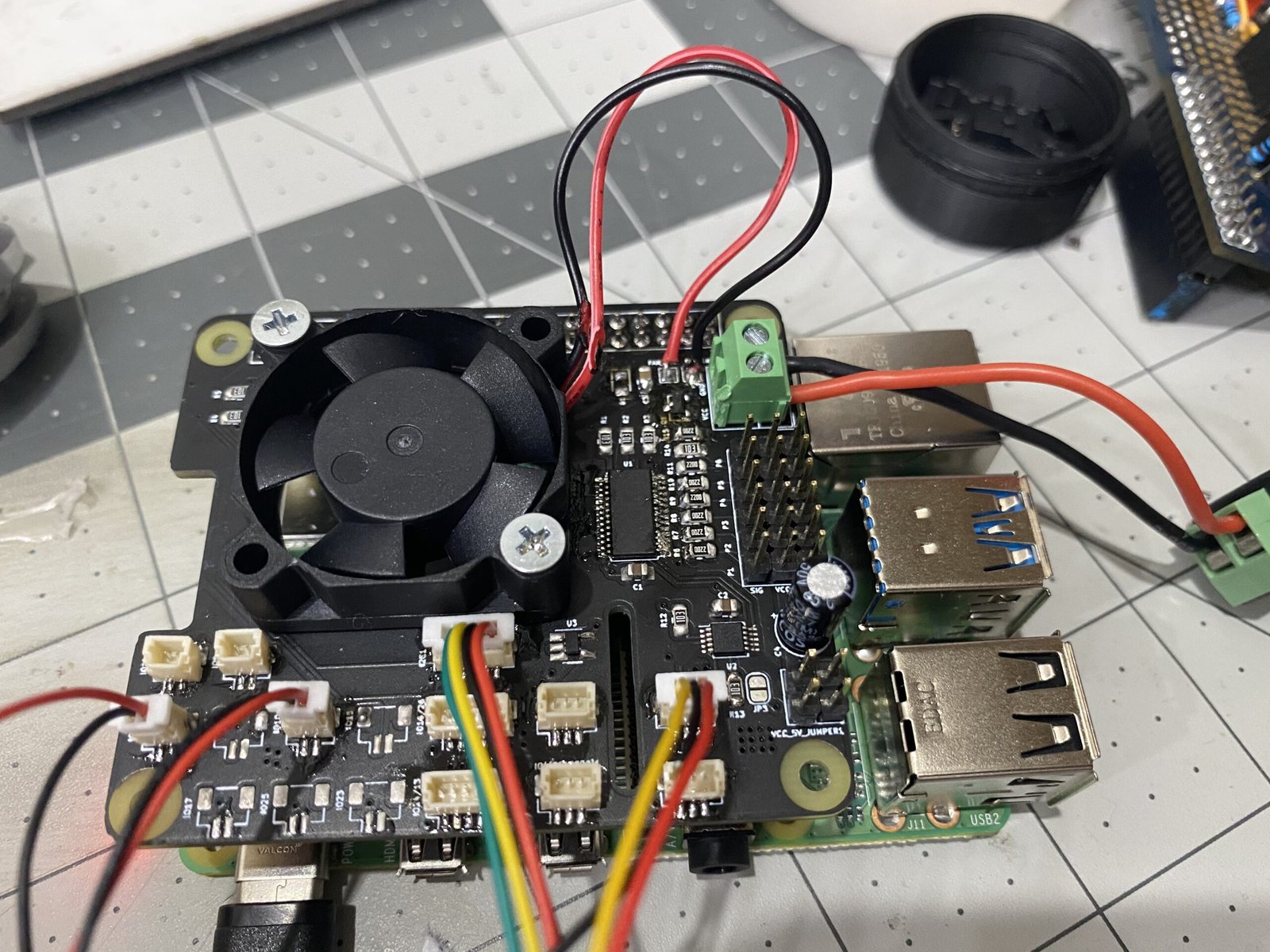

Setting Up PID Fan Control in OctoPrint

Setting up PID fan control in OctoPrint involves a few key steps, but once completed, it can greatly enhance your 3D printing experience. The process begins with accessing the appropriate settings in OctoPrint and making sure your printer’s firmware supports PID fan control.

- Accessing the Terminal: Begin by navigating to the terminal in OctoPrint. This is where you’ll input the necessary commands to adjust your fan’s PID settings.

- Running a PID Tune: Input the command to start a PID tune for your fan. This will typically be something like

M106followed by specific parameters to initiate the tuning process. The PID tune will automatically adjust the fan speed and measure the response to determine the optimal PID values. - Saving the Settings: Once the tune is complete, you’ll need to save the settings to your printer’s EEPROM (Electrically Erasable Programmable Read-Only Memory) to ensure they are retained after restarting your printer.

- Fine-Tuning the Parameters: After the initial setup, you may want to fine-tune the PID parameters based on your specific printing conditions. This can involve adjusting the Proportional, Integral, and Derivative values individually to achieve the best results.

Advantages of Using PID Fan Control

The benefits of using PID fan control in OctoPrint are numerous and can make a substantial difference in your 3D printing outcomes. These advantages include:

- Consistent Print Quality: By maintaining a stable temperature, PID fan control helps prevent common issues such as warping or layer shifting, resulting in cleaner and more accurate prints.

- Improved Efficiency: With precise fan control, your printer operates more efficiently, potentially reducing the time and energy required to complete a print.

- Enhanced Material Compatibility: Some materials require very specific temperature conditions. PID fan control allows you to meet these requirements more easily, expanding the range of materials you can work with.

Common Challenges and How to Overcome Them

While PID fan control offers significant benefits, it can also present some challenges, particularly for beginners. One common issue is the initial setup, which can be a bit daunting. However, by following a step-by-step guide and taking the time to understand the basics of PID control, you can overcome this hurdle.

Another challenge is finding the right balance between the PID parameters. Too much of one component (e.g., Proportional) and too little of another (e.g., Derivative) can lead to unstable fan speeds and poor temperature control. The key is to make incremental adjustments and test the results thoroughly.

Practical Tips for Optimizing PID Fan Control

To get the most out of PID fan control in OctoPrint, consider the following tips:

- Start with Conservative Settings: Begin with conservative PID values and gradually adjust them as you become more familiar with how they affect your fan speed and temperature stability.

- Monitor Performance Closely: Use OctoPrint’s real-time monitoring tools to keep an eye on your printer’s performance. This will help you identify any issues early and make the necessary adjustments.

- Experiment with Different Materials: Try using PID fan control with different printing materials to see how it affects their performance. This can be particularly useful when working with materials that are sensitive to temperature fluctuations.

How to Troubleshoot Issues with PID Fan Control

If you encounter problems while using PID fan control in OctoPrint, there are several troubleshooting steps you can take:

- Check the Firmware: Ensure that your printer’s firmware supports PID fan control. Some older firmware versions may not include this feature, in which case you might need to update your firmware.

- Review the PID Settings: If your fan speed is fluctuating excessively, it may be due to incorrect PID settings. Try running the PID tune again and adjusting the parameters as needed.

- Look for Software Conflicts: In some cases, other plugins or software settings in OctoPrint may interfere with PID fan control. Disable any unnecessary plugins and see if that resolves the issue.

Conclusion

OctoPrint PID fan control is a powerful feature that can greatly enhance your 3D printing experience by providing precise control over fan speed and temperature. By taking the time to understand and properly set up this feature, you can achieve more consistent and higher-quality prints. Whether you’re a novice or an experienced 3D printer, mastering PID fan control in OctoPrint is a worthwhile endeavor that can unlock new possibilities in your 3D printing projects.

FAQs

What is PID fan control in OctoPrint?

PID fan control in OctoPrint is a method for regulating the fan speed in a 3D printer using a PID control loop to maintain a consistent temperature.

Why should I use PID fan control in 3D printing?

Using PID fan control ensures stable temperatures during printing, which is crucial for achieving high-quality prints, especially with temperature-sensitive materials.

How do I set up?

Setting up PID fan control involves accessing the terminal in OctoPrint, running a PID tune, saving the settings, and fine-tuning the PID parameters for optimal performance.

Can PID fan control improve print quality?

Yes, by maintaining a consistent temperature, PID fan control helps prevent issues such as warping or layer shifting, leading to cleaner, more accurate prints.

What are the common challenges with PID fan control?

Common challenges include the initial setup and finding the right balance between PID parameters. However, with careful adjustments and testing, these challenges can be overcome.

What should I do if my PID fan control isn’t working properly?

If PID fan control isn’t working as expected, check your firmware, review the PID settings, and look for any software conflicts within OctPrint.